chart 1

chart 2

chart 3

chart 4

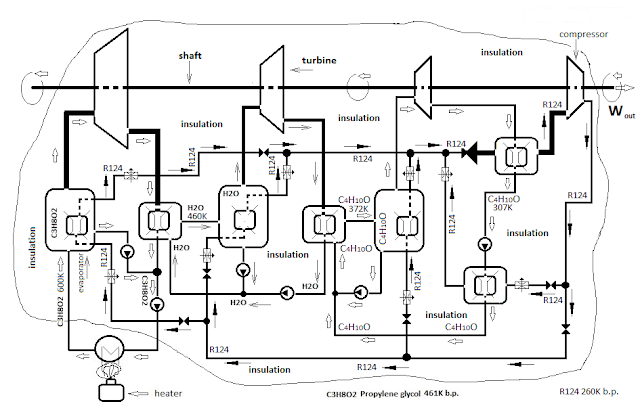

Charts 3 and 4 am figuring engines of the same capacity of the converters of heat into mechanical energy as chart 1 and 2, but here I have no imaginary "free" cooler. Close the cycle by using force to close the cycle - cooling gas as I use cooler - External combustion - internal cooling engines. Waste heat (20%) cooler return it in the evaporators of the unit. Accept that besides waste heat in evaporators returns heat equal to the force I used to close the cycle + 20% of heat . So aggregates of diagrams 3 and 4 for the same capacity of the turbines will produce 40% less mechanical energy than units with imaginary "free cooling". If a cooler is free - 100kW, and if cooling is "paid" - 60 kW of power.

External combustion 100kW

External combustion - internal cooling - 60kW

for the same capacity of the turbine (piston / cylinder)

chart 5

chart 6

On chart 5 am drawn external combustion engine with real free cooler - environment. On chart 6 - engine by method - external combustion - internal cooling, with the same parameters.

Assume - on 20% waste heat - 100kW power of external combustion engine

Verdict:

1.On 20% waste heat - 100kW useful power of external combustion engine

On 20% waste heat - 60kW useful power of external combustion - internal cooling engine for one and the same capacity of the turbines.

2.For the same capacity of the converters of heat into mechanical energy engine - external combustion - internal cooling gives 40% less mechanical power, but uses 40% less heat - no waste heat.

3. Another small deficiency on engine by external combustion method - necessarily need heater to heat the hot part, so that the engine to have a cold part. On the engine by external combustion - internal cooling method the cold part we create it, so that we can use any heat, including of heater.

chart7

chart 8

Let's

take one external combustion engine as

the chart 2 filled with the same three working substances

(ammonia, R41, R14) and go to Planet X, which has an atmosphere with a

temperature of 130K - chart 7. Now, for such a unit will have free cooling,

as we have in mind that the last working substance (R14) has a boiling point of

145K, and the atmosphere of Planet X on which the temperature is 130K. Light a

burner and heat ammonia to 290K. I accept that for a 20% waste heat engine will

gives 100kW mechanical energy.

Redesign

the External combustion engine to an External

combustion- internal cooling by removing heat exchanger which cools the last

working substance to liquefy in the atmosphere of the planet X - chart 8. Set in its

place cooler loaded with nitrogen. Waste heat set it back into evaporators. As

I said above, now I lose 40% of the power output of the unit, but also

decreased 40% fuel in the burner.

On Planet X unit working with these substances can only work with heater, whether

external combustion engine or an external combustion - internal cooling engine.

On

Earth we do not need a heater - Sun heated the atmosphere at 290K and hence

heat ammonia. But on Earth mandatory for these working substances unit must be performed by External combustion - Internal cooling method, because no natural cold part.

Conclusions:

Engine

- external combustion

1

With external combustion engine ever we need a heater.

2

In these units have free cooling

3.

We have waste heat

Engine

- External combustion- internal cooling

1 Heater is not mandatory

2

For the same capacity of converters of heat into mechanical energy

(turbines; pistons / cylinders) has a lower power than external combustion

engine

3

No waste heat

Summary

of advantages and disadvantages of the method for converting heat into

mechanical energy - External combustion - internal cooling

When

using External combustion engine we pay for heating and cooling is free.

When

using External combustion - internal

cooling engine is not required to pay for heating, but must pay for cooling.

06 January 2016

I made some mistakes in the calculations for external combustion - internal cooling. True comparison between the two engines in the same capacity of the converters of heat into mechanical energy should look like:

At 100 kW useful power and 20 kW waste heat

1. External combustion engine:

120 kW power of the heater

100 kW useful power

20 kW waste heat

2. External combustion - internal cooling engine:

80 kW power from the heater

80 kW useful force

0 kW waste heat

20 kW from the gross mechanical power is converted into heat (so the net power becomes: 100-20 = 80 kW)

+ 20 kW waste heat - these two amounts of heat returned to the evaporator(s). This requires to reduce the power output of the heater wiht 40 kW : 120 - (20 + 20) = 80 kW

It would be good to think about things in depth before presenting them to readers. I beg your pardon!

:) :) For my next invention I intend to never wrong :) :)

06 Jan 2016

Svetozar the Cold